Diecast Metals Advantages Overview

Diecast metals have become a cornerstone of modern manufacturing, offering a versatile and efficient solution for producing complex metal components. The die casting process involves injecting molten metal under high pressure into reusable molds, known as dies, creating parts with intricate designs and precise dimensions. This method offers numerous advantages over other manufacturing techniques, making it a preferred choice across various industries. From automotive to consumer electronics, diecast metals are utilized for their superior performance, cost-effectiveness, and design flexibility. Understanding the core advantages of diecast metals is crucial for anyone involved in product design, engineering, or manufacturing. The following sections will delve into the top 5 advantages, illustrating why die casting is a dominant force in modern production.

Strength to Weight Ratio

One of the most significant benefits of using diecast metals is their exceptional strength-to-weight ratio. This characteristic is particularly important in applications where minimizing weight is crucial without compromising structural integrity. Aluminum and magnesium, two commonly used diecast metals, offer high strength while remaining relatively lightweight. This makes them ideal for the automotive industry, where fuel efficiency and vehicle performance are directly impacted by weight reduction. Aircraft components, power tools, and even sporting goods also benefit from the superior strength-to-weight ratio of diecast metals. The ability to create robust, lightweight parts allows for improved product performance, reduced material costs, and enhanced overall efficiency. Furthermore, the die casting process allows for precise control over the metal’s structure, optimizing the strength properties based on the specific application requirements.

Mechanical Properties Benefits

The mechanical properties of diecast metals are a major reason for their widespread use. The high-pressure injection process results in a dense, fine-grained structure, contributing to enhanced tensile strength, yield strength, and hardness. This ensures the components can withstand significant stress and strain without deformation or failure. Diecast parts also exhibit excellent dimensional stability, meaning they maintain their shape and size even under varying operating conditions. This is particularly crucial in applications where tight tolerances and precise fits are essential. The choice of metal alloys allows for tailoring the mechanical properties to meet specific performance requirements. For example, zinc alloys are chosen for their excellent wear resistance, while aluminum alloys offer a balance of strength, weight, and corrosion resistance. These superior mechanical properties make diecast metals a reliable choice for high-performance applications.

Complex Geometry and Design Freedom

Die casting excels in producing complex geometries and intricate designs that would be difficult or impossible to achieve with other manufacturing methods. The high-pressure injection of molten metal into the die allows for the creation of intricate features, such as thin walls, fine details, and complex internal geometries. This design freedom empowers engineers and designers to create innovative products with enhanced functionality and aesthetic appeal. It allows for incorporating multiple features into a single part, reducing the need for assembly and simplifying the overall manufacturing process. This capability is particularly valuable in industries where miniaturization and compact designs are paramount, such as electronics and medical devices. The ability to produce complex shapes in a single step also reduces material waste and the need for secondary machining operations, leading to significant cost savings.

Intricate Designs and Features

The die casting process facilitates the creation of intricate designs with exceptional detail. This is due to the precision with which the molten metal fills every crevice and contour of the die. Die casting can produce parts with fine surface finishes, sharp corners, and precise dimensions. This is especially beneficial for parts that require complex geometries, such as those found in automotive engines, consumer electronics, and medical equipment. The ability to integrate complex features, such as threads, bosses, and mounting points directly into the cast part, eliminates the need for secondary operations. This not only streamlines the manufacturing process but also reduces the risk of errors and defects. This capability ensures the highest level of detail and accuracy, resulting in superior product performance and appearance.

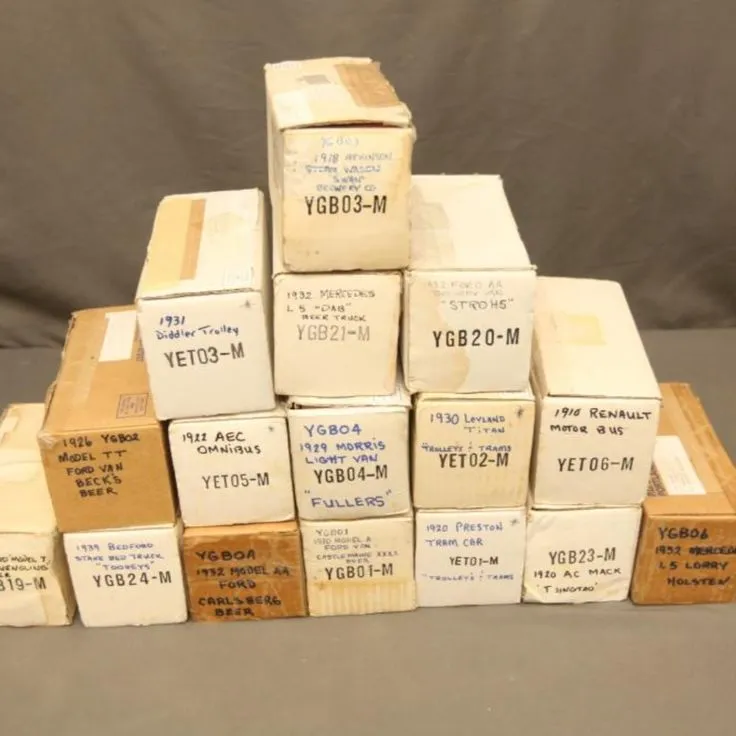

High Production Rates and Efficiency

Die casting is known for its high production rates and overall efficiency, making it an ideal choice for mass production applications. The automated nature of the die casting process allows for rapid production cycles, with parts being produced in seconds. This high throughput is achieved through the use of reusable dies and automated equipment. This rapid cycle time translates to increased production volumes and faster delivery times. The process is highly repeatable, ensuring consistent part quality and dimensional accuracy. The efficiency of die casting extends beyond production speed. It minimizes material waste, reduces the need for secondary machining operations, and offers excellent dimensional control. These factors collectively contribute to lower production costs and improved profitability, making die casting a preferred manufacturing method for high-volume production runs.

Faster Manufacturing Processes

Compared to alternative manufacturing processes, die casting offers significantly faster production cycles. The ability to quickly inject molten metal into the die, solidify it, and eject the finished part is a key factor in the high production rate. The cycle time depends on the size and complexity of the part, but it is typically measured in seconds. This quick turnaround is achieved through the use of advanced die casting machines and optimized process parameters. In addition to the speed of production, die casting requires minimal post-processing. Often, the parts are ready for use straight out of the die, minimizing the need for secondary operations like machining or finishing. This streamlined approach accelerates the overall manufacturing process, reducing lead times and enabling manufacturers to respond quickly to market demands.

Cost-Effectiveness and Material Savings

Die casting offers significant cost savings compared to other manufacturing methods, particularly for high-volume production runs. The efficient use of materials, reduced labor costs, and minimal waste contribute to lower per-part expenses. The reusable nature of the dies also spreads the tooling costs over a large number of parts, making the process economically advantageous. The ability to produce complex shapes in a single step eliminates the need for multiple machining operations, reducing both time and costs. The process typically yields parts with a net shape, requiring little to no finishing, further reducing manufacturing expenses. The choice of metal alloys also plays a role in cost optimization. The possibility of using recycled materials in the die casting process also contributes to further cost savings and promotes sustainable manufacturing practices. These factors collectively make die casting a highly cost-effective manufacturing solution.

Reduced Waste and Material Efficiency

Die casting is a relatively environmentally friendly process due to its high material efficiency and reduced waste. The process minimizes material waste because it produces parts close to their final shape, requiring little to no machining or trimming. The molten metal is injected directly into the die cavity, and any excess material, such as sprues and runners, can be recycled and reused. This closed-loop material management system reduces waste and minimizes the environmental impact of the manufacturing process. Moreover, the use of recycled metal alloys further promotes sustainability by conserving natural resources and reducing energy consumption. By minimizing waste and maximizing material utilization, die casting supports responsible manufacturing practices and contributes to a more sustainable future. This efficiency is critical in an era where environmental concerns are at the forefront of manufacturing decisions.

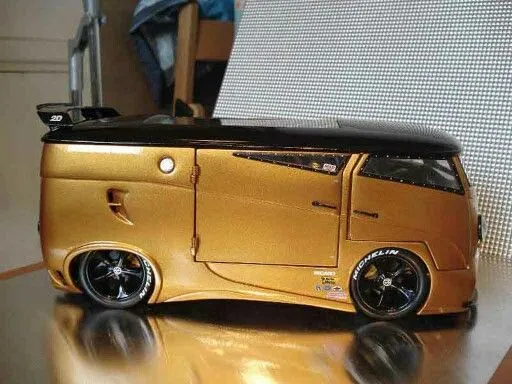

Surface Finish and Finishing Options

Diecast metals offer excellent surface finish and a wide range of finishing options, enhancing both the appearance and functionality of the components. The high-pressure injection process ensures a smooth surface finish, often eliminating the need for additional surface preparation. This smooth surface is ideal for various finishing treatments, such as painting, plating, powder coating, and anodizing. These finishing options not only improve the aesthetics of the parts but also provide corrosion resistance, wear resistance, and other desirable properties. The ability to achieve a high-quality surface finish makes diecast metals a preferred choice for products that require a visually appealing and durable finish. This versatility allows manufacturers to tailor the surface finish to meet the specific needs of the application, whether it’s for aesthetic reasons or for protection against environmental factors.

Excellent Surface Quality

The surface quality of diecast metal parts is generally excellent, with a smooth and consistent finish. This is achieved through the high-pressure injection of molten metal into the die cavity, which forces the metal to conform to the die’s surface details. This process results in parts with a fine surface texture and minimal surface defects. The smooth surface finish provides an ideal base for various finishing treatments, enhancing the product’s appearance and durability. This eliminates or reduces the need for extensive surface preparation prior to finishing, saving time and costs. The superior surface quality also allows for precise dimensional control and improved part performance, making die casting a reliable choice for applications requiring high aesthetic and functional standards. This is extremely important for products such as automotive parts where appearance is key.

In conclusion, diecast metals offer a compelling combination of advantages that make them a preferred choice for manufacturers across various industries. The exceptional strength-to-weight ratio, design freedom, high production rates, cost-effectiveness, and excellent surface finish contribute to their widespread use. From automotive components to consumer electronics, diecast metals enable the production of high-quality, durable, and cost-effective products. By understanding these top 5 advantages, designers, engineers, and manufacturers can leverage the benefits of die casting to optimize their product designs, streamline their manufacturing processes, and achieve a competitive edge in the market. As technology advances, die casting continues to evolve, offering even greater capabilities and benefits for the future of manufacturing.