Understanding Diecast Tools What You Need

Diecast model collecting is a rewarding hobby, and having the right tools can significantly enhance your experience. Diecast tools are specialized instruments designed to help collectors maintain, repair, and customize their models. These tools range from simple screwdrivers and tweezers to more advanced items like magnifying glasses and cutting tools. Understanding the basics of these tools is the first step toward becoming a proficient diecast enthusiast. Proper tools not only facilitate maintenance and repairs but also allow for detailed inspections and customizations that can truly make your collection stand out. With the right tools, you can ensure your models remain in pristine condition and you can explore the full potential of the hobby.

Essential Diecast Tool Types

Several essential tools are indispensable for diecast model collectors. Each tool serves a specific purpose, contributing to the overall care and enhancement of your collection. A well-rounded toolkit will cover various needs, from basic maintenance to more intricate detailing tasks. Investing in these essential tools is a crucial step in optimizing your diecast collecting journey. Understanding the function of each tool will help you use them effectively and safely, ensuring that you can handle your models with confidence and precision. Remember, the right tools are a collector’s best asset, helping to preserve and showcase your treasures.

Screwdrivers The Collector’s Best Friend

Screwdrivers are fundamental to any diecast tool kit. They are essential for disassembly, reassembly, and any adjustments requiring loosening or tightening screws. A set of small precision screwdrivers, including Phillips head and flathead variations, is a must-have. Ensure the screwdrivers are made of high-quality steel to prevent stripping the screws or damaging the model. Ergonomic handles will provide a comfortable grip, allowing for better control and reducing fatigue during detailed work. Having a variety of sizes ensures you’re prepared for any screw type found in your diecast models. Regular use of these tools is often necessary to maintain and repair the cars.

Tweezers for Precision Handling

Tweezers are invaluable for handling small parts, decals, and delicate components. They allow you to grip and maneuver tiny pieces with precision, reducing the risk of damage or loss. Consider investing in several types of tweezers, including pointed, curved, and flat-tipped options. Pointed tweezers are great for fine work, while curved tweezers can reach hard-to-access areas. Flat-tipped tweezers are ideal for handling decals without creasing them. High-quality tweezers made of stainless steel are durable and offer good grip. Using tweezers helps to prevent fingerprints and oils from damaging the models. Good tweezers are essential when dealing with intricate details and miniature parts in your collection.

Magnifying Glasses for Detailed Inspection

A magnifying glass or a head-mounted magnifier is crucial for examining the intricate details of your diecast models. These tools enhance your ability to spot imperfections, assess the condition of the models, and perform delicate tasks. Magnification helps you view tiny features that might be missed with the naked eye. Choose a magnifier with multiple lenses to vary magnification levels based on your task. LED illumination is also a beneficial feature as it provides better lighting and reduces eye strain. These tools are especially helpful for collectors interested in detailed restorations or modifications, allowing a clearer view of the model’s components. Using a magnifying glass is key to fully appreciating the craftsmanship.

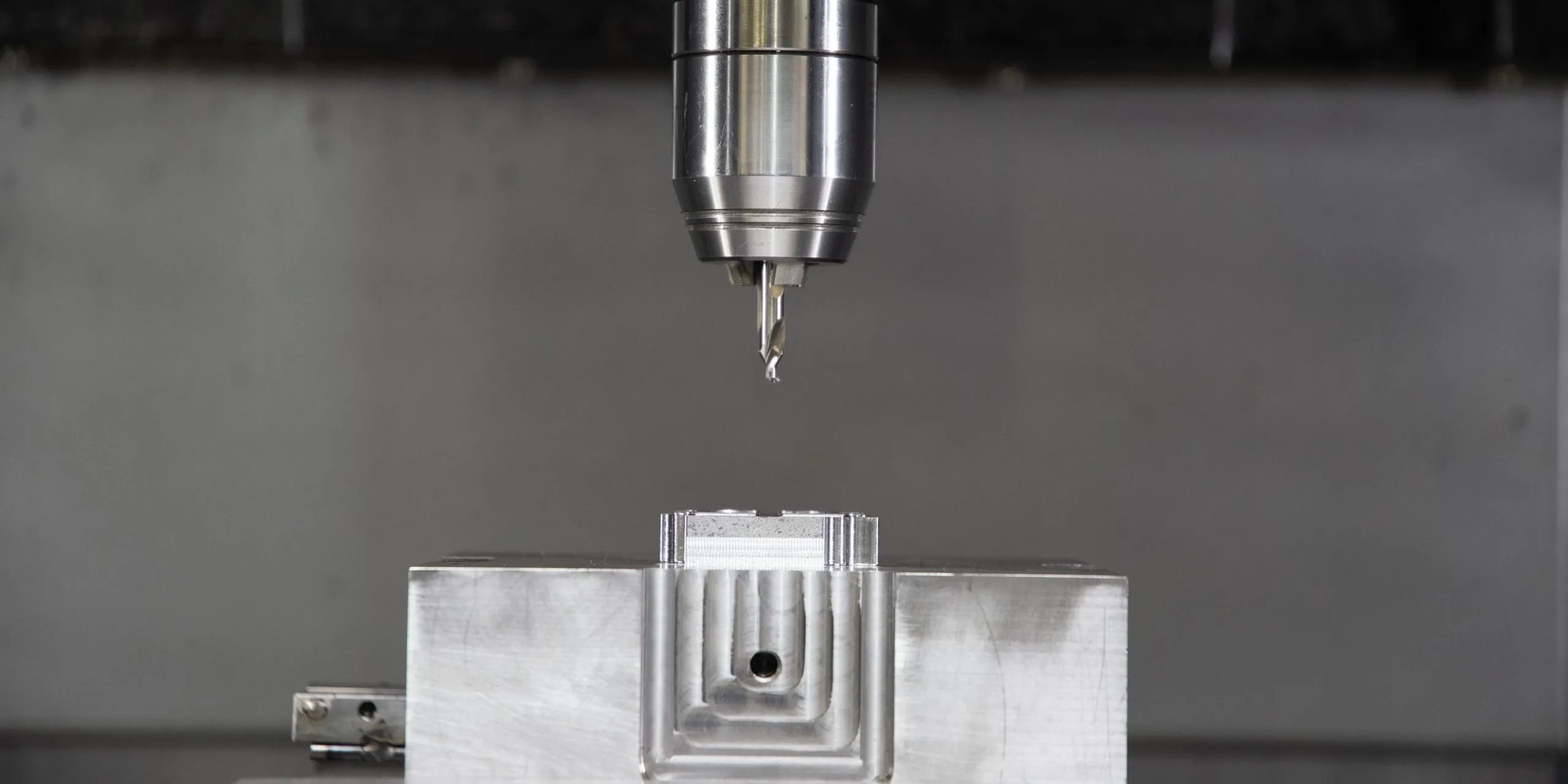

Cutting Tools for Diecast Detailing

Cutting tools are used for trimming flash, removing parts, and other detailing tasks. Hobby knives, with replaceable blades, offer precision and control. A cutting mat is essential to protect your workspace and the knife blades. Side cutters or flush cutters are useful for removing small plastic parts. Be cautious when using these tools and always cut away from yourself. Proper lighting and a steady hand are necessary to prevent mistakes and damage. These tools are important if you want to customize or repair your models. Always prioritize safety and use appropriate protective gear when handling cutting tools.

Choosing the Right Diecast Tool

Selecting the right diecast tools can be a daunting task, but several factors can guide your decisions. Consider the quality of the materials, the design, and the intended use. Tools made from high-quality materials, such as stainless steel or hardened steel, will offer better durability. Ergonomic designs, with comfortable grips, make extended use more pleasant. Assess what tasks you plan to perform, such as basic maintenance, detailing, or major modifications, when selecting the tools. Consider your budget, but remember that investing in higher-quality tools usually pays off in the long run. Researching the tools, reading reviews, and talking with other collectors can help you narrow down your choices.

Factors to Consider When Buying Tools

When buying diecast tools, there are several important factors to keep in mind. Quality is paramount; look for tools made from durable materials that can withstand frequent use. Consider the tool’s size, weight, and ergonomic design to ensure comfort and usability. Read reviews to gauge the tool’s performance and longevity. Evaluate the variety of tools in any set, ensuring it meets your present needs. Assess the availability of replacement parts, such as blades or tips, to keep your tools in good working order. Compare prices from different retailers, but prioritize quality over cost to avoid purchasing tools that will quickly fail. Remember that proper tool care and maintenance will extend the life of your tools.

Tool Quality and Durability

The quality and durability of your tools directly impact your collecting experience. Invest in tools made from robust materials like stainless steel or high-carbon steel, as these will resist wear and tear. Look for tools with well-crafted designs that are able to withstand the rigors of frequent use. Poor-quality tools can break, strip screws, or damage your models. Check for comfortable handles and proper balance to enhance control and reduce fatigue. Purchasing quality tools upfront can save you money and frustration in the long run. Regular maintenance, such as cleaning and proper storage, will further extend the lifespan of your tools. Prioritizing quality ensures that your investment in tools will last for many years.

Getting Started with Diecast Tools

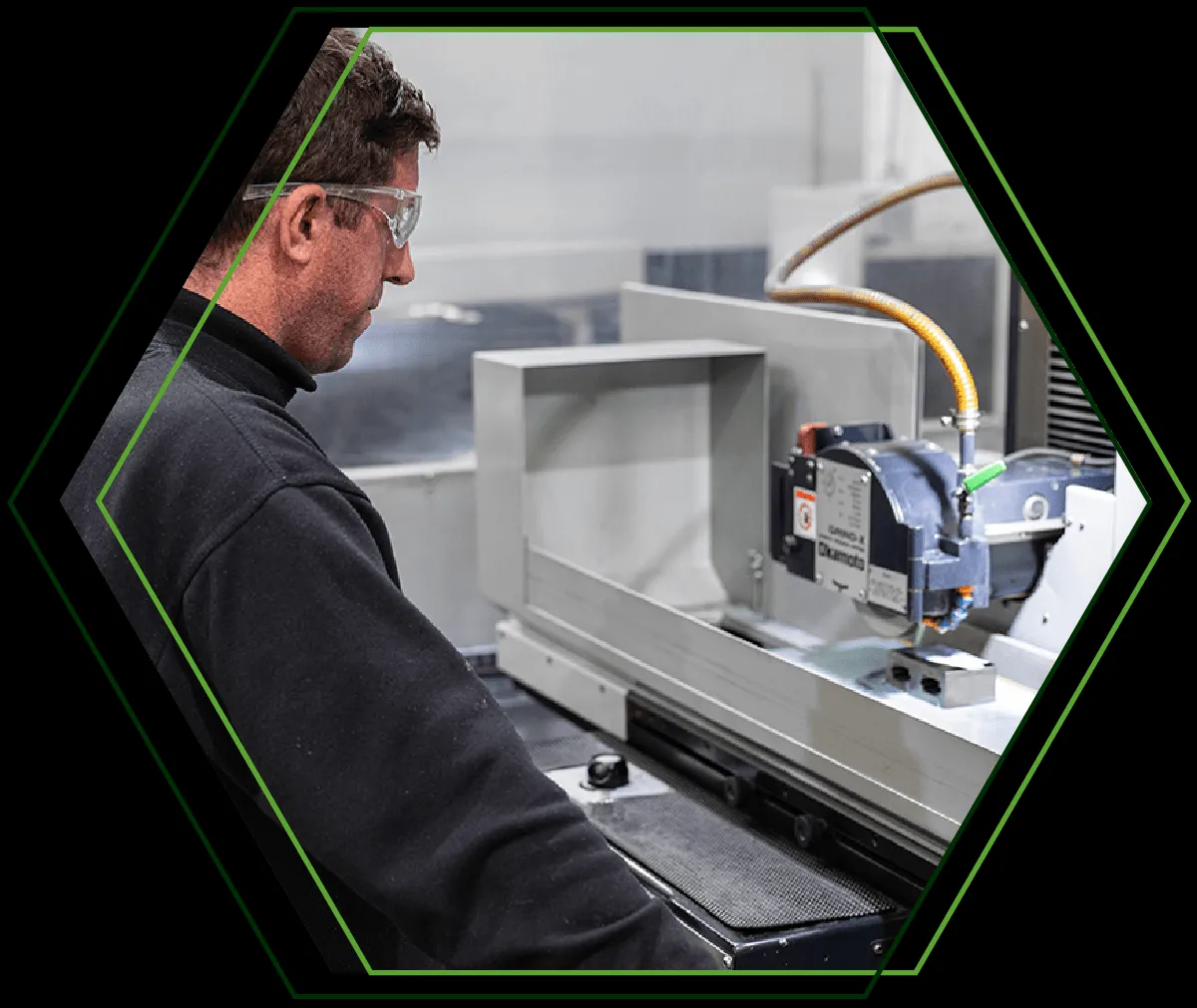

Starting with diecast tools requires some preparation and the right mindset. Begin by gathering the essential tools mentioned previously, such as screwdrivers, tweezers, and a magnifying glass. Organize your workspace with good lighting and a clear surface to work on. Practice using your tools on less valuable models or scrap parts to hone your skills. Start with simple tasks like unscrewing and reassembling a model before attempting more complicated projects. Always work slowly and methodically, especially when handling delicate parts. Watch tutorials and read guides to learn techniques. Remember that practice makes perfect, and don’t be afraid to experiment and learn from your mistakes.

Preparing Your Workspace

A well-prepared workspace is key to a successful diecast collecting experience. Choose a well-lit area with plenty of space to work. A cutting mat is essential for protecting your work surface. Keep your tools organized, perhaps in a toolbox or a dedicated storage system. Have containers ready for small parts like screws or decals to prevent loss. Clear your workspace of clutter, as it can lead to mistakes or damage to your models. Good lighting will minimize eye strain. Consider a comfortable chair to help you maintain proper posture during long sessions. Preparing your workspace will significantly improve your efficiency and enjoyment of the hobby.

Basic Diecast Tool Techniques

Mastering basic techniques is essential for effective use of diecast tools. When using screwdrivers, apply gentle but firm pressure and avoid over-tightening screws. When working with tweezers, grip parts near the center to prevent bending. When using cutting tools, always cut away from yourself and use a sharp blade. For cleaning models, use a soft brush or cloth and avoid harsh chemicals. Always take your time and be patient, especially when handling fragile components. Remember that the goal is to preserve and enhance your models, so practice, patience, and the right techniques are key.

Cleaning and Maintenance of Your Tools

Regular cleaning and maintenance will prolong the life of your diecast tools. After each use, wipe down your tools with a soft cloth to remove debris. Use a small amount of lubricant on moving parts. Store your tools in a dry place. Sharpen or replace cutting blades when they become dull. Inspect your tools for wear and tear regularly. Proper care ensures that your tools remain in optimal condition and function effectively for years to come. A well-maintained toolkit is a sign of a dedicated collector.