What is Diecast to RC Conversion?

Diecast to RC conversion is the fascinating process of transforming static diecast model cars into fully functional radio-controlled (RC) vehicles. This involves removing the original components of a diecast model and replacing them with RC electronics, including a motor, electronic speed controller (ESC), receiver, servo, and battery. The conversion allows enthusiasts to enjoy the aesthetic appeal of detailed diecast models while experiencing the thrill of controlling them on the move. This DIY project combines craftsmanship with technical skills, offering a rewarding experience for hobbyists and model car enthusiasts. The appeal lies in the ability to personalize and enhance a model, creating a unique RC car that reflects individual preferences and specifications. It’s a way to breathe new life into a static model, giving it dynamic functionality and adding a new dimension to the hobby of model car collecting and customization. The process ranges from simple modifications to more complex builds, providing opportunities for continuous learning and skill development.

Benefits of Diecast to RC Conversion

Converting a diecast model to RC offers numerous benefits. First and foremost is the enhanced enjoyment of your model. Instead of a static display, you gain a dynamic, interactive experience. RC conversion also allows for a high degree of personalization. You can choose specific RC components to tailor the car’s performance, handling, and appearance. This includes selecting motors for speed and torque, choosing servos for precise steering, and customizing the car’s overall look. Furthermore, the conversion process provides a valuable learning experience. It introduces you to the fundamentals of RC car technology, including electronics, mechanics, and basic engineering principles. Finally, it provides a creative outlet. The ability to design, build, and modify your RC car encourages problem-solving skills and fosters a sense of accomplishment. It is a rewarding hobby that combines technical expertise with a passion for model cars, offering a unique blend of creativity and mechanical skill.

Gathering Your Supplies

Before starting your RC conversion project, gathering the right supplies is crucial. Begin with the diecast model you want to convert. Consider the model’s scale, construction, and the space available for RC components. Next, you’ll need the essential RC components. These include a motor (brushed or brushless), an electronic speed controller (ESC) to manage the motor’s speed and direction, a receiver to pick up radio signals from the transmitter, a servo for steering, and a battery to power the system. Don’t forget the transmitter, which controls the car. You’ll also need various tools like screwdrivers, pliers, wire strippers, a soldering iron (and solder), a hobby knife, and possibly a Dremel or rotary tool for modifications. Finally, gather any necessary adhesives, such as CA glue or epoxy, for assembling or modifying parts. A well-prepared workspace and organized supplies will ensure a smoother, more efficient conversion process, setting the stage for a successful and enjoyable project.

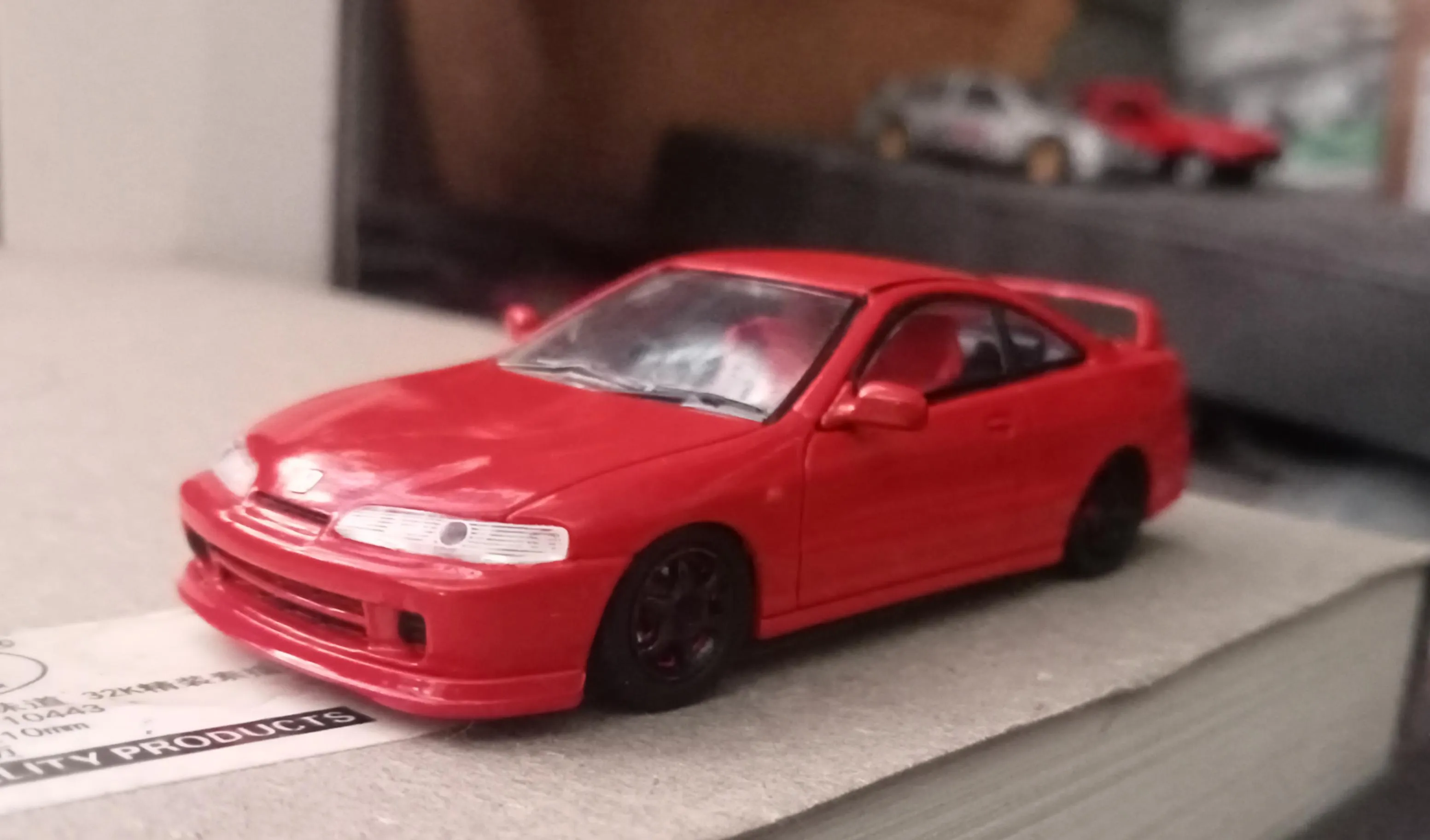

Choosing the Right Diecast Model

Selecting the right diecast model is critical for a successful RC conversion. Consider the scale of the model, as this will determine the size of the RC components you need. Common scales include 1:18, 1:24, and 1:43, each offering different levels of space for installation. The model’s construction also matters. Look for models with accessible interiors and chassis, which make component installation easier. Evaluate the material of the chassis; metal chassis can offer durability but may require modifications. Also, consider the level of detail on the model. High-detail models can enhance the final appearance, but the added features can sometimes complicate the conversion process. Finally, research the model’s popularity and the availability of replacement parts, as you may need to source parts during the build. Taking these factors into account will increase the chances of a satisfying and manageable RC conversion project. This careful selection process is the foundation for a rewarding and successful conversion.

Essential Tools for Conversion

Having the correct tools is essential for a smooth and successful diecast to RC conversion. A set of small screwdrivers (Phillips and flathead) is crucial for disassembling and reassembling the model. Pliers, including needle-nose pliers, are needed for handling small parts and wires. Wire strippers and crimpers are necessary for preparing and connecting wires, and a soldering iron with solder is used to create secure electrical connections. A hobby knife or X-Acto knife is helpful for trimming and modifying plastic components. A Dremel or rotary tool with various bits can be invaluable for cutting, grinding, and shaping the chassis or other parts to fit the RC components. Additionally, a set of hex wrenches or Allen keys might be necessary for certain screws. Finally, a measuring tool (ruler or calipers) is useful for precise measurements and modifications. Having these tools prepared and organized will greatly enhance the efficiency and precision of your conversion project. A well-equipped workspace translates into a better and more enjoyable building experience.

Disassembly and Preparation

Disassembly and preparation are the foundational steps in the RC conversion process. Begin by carefully disassembling the diecast model. Document the process with photos, especially if you’re not familiar with the model’s construction. This will help you remember how everything goes back together. Remove the interior components, such as seats, dashboards, and any molded interior details, which may interfere with the placement of the RC components. Next, remove any existing chassis parts, wheels, and axles. Carefully store all the original parts in a safe place. Assess the chassis for modifications. You might need to remove sections, drill holes, or create mounting points to accommodate the new RC components. Preparing the chassis is often the most time-consuming part of the conversion but ensures all components fit correctly and function effectively. Precision and patience in this initial phase will save you headaches later during reassembly and testing. Consider protecting the model’s paint during the modifications to prevent damage, which will help preserve its aesthetic appeal.

Removing the Original Components

Removing the original components of the diecast model is a critical step in the conversion process, clearing the way for the installation of RC parts. Start by carefully detaching the interior components such as the seats, dashboard, and any existing electronics. These parts may be glued or screwed in place, so take your time to avoid damaging them or the model itself. Next, remove any original chassis parts like the wheels, axles, and suspension components. You may need to use small screwdrivers, pliers, or a hobby knife to carefully loosen or detach these parts. Make sure to keep track of all screws, clips, and other small fasteners. It’s also helpful to take photos during this process to serve as a visual reference when reassembling the model. Properly removing the original parts ensures that the chassis is ready to accept the RC components, paving the way for a successful conversion. Remember to work methodically and with patience to prevent accidental damage to the model’s body or delicate features.

Preparing the Chassis

Preparing the chassis is a crucial step to ensure that the RC components fit properly and function effectively. This may involve several modifications, depending on the model and the size of the RC components. Start by assessing the chassis for potential interference issues. You may need to remove sections of the chassis or trim away any unnecessary material to create space for the motor, ESC, receiver, and battery. Use a Dremel or rotary tool with appropriate cutting and grinding bits to perform these modifications. Consider the location of mounting points for the motor and servo. You may need to drill holes in the chassis or fabricate custom mounts to securely attach these components. It is important to measure twice and cut once. Ensure all modifications are precise and aligned with the overall design. These chassis modifications are essential for a successful RC conversion, providing the necessary structure and space for the RC components, which facilitates their integration into the diecast model. Always prioritize the structural integrity of the chassis while making these modifications.

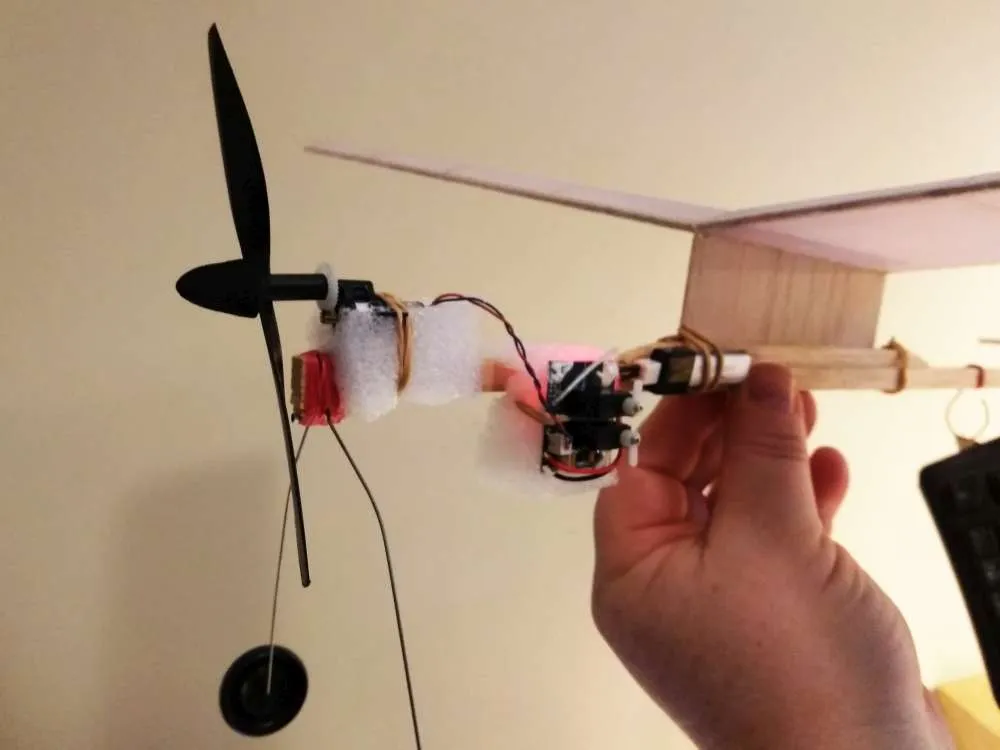

Installing the RC Components

Installing the RC components is the heart of the conversion process. Start with the motor and ESC. Mount the motor to the chassis using appropriate screws or adhesives, ensuring it’s securely positioned and aligned with the drive system. Next, install the ESC, placing it in a location that allows easy access to the wiring and connections. Install the receiver, which picks up radio signals from the transmitter. Position it so it is protected from impacts and interference. Mount the servo for steering, attaching it to the chassis and connecting it to the steering mechanism. Carefully route all wires to avoid snags or interference with moving parts. Use double-sided tape, zip ties, or specialized RC component mounts to secure the electronics. Make sure all connections are secure and well-insulated. Proper installation ensures the RC system operates smoothly and reliably. Double-check your work as you go to prevent errors and ensure the long-term functionality and enjoyment of your converted model.

Mounting the Motor and ESC

Mounting the motor and ESC is a crucial step in converting your diecast to RC. First, choose an appropriate motor for the scale and desired performance of the RC car. Position the motor in the chassis, paying attention to the alignment with the drive gear or belt system. Secure the motor using screws, adhesives, or custom-fabricated motor mounts. Ensure the motor is firmly attached and does not vibrate excessively. Then, mount the ESC, selecting a spot that allows good access to the wiring and is protected from potential damage. Use double-sided tape, or zip ties. Connect the motor wires to the ESC, carefully matching the polarities. The ESC should be installed in a location where it gets adequate airflow to prevent overheating. Consider the position of the battery and its connection to the ESC. The placement of the motor and ESC directly affects the car’s performance and reliability. Careful and precise mounting is therefore key to a successful and enjoyable RC conversion. Testing the setup before final assembly helps ensure everything functions correctly.

Wiring the Electronics

Wiring the electronics is a critical aspect of the RC conversion process, connecting all the components to create a functional system. Start by connecting the motor wires to the ESC, ensuring the correct polarity. Then, connect the receiver to the ESC and servo, using the appropriate connectors and channels. The receiver receives signals from the transmitter and sends signals to the servo (for steering) and ESC (for speed and direction). Be sure to route the wires neatly, using zip ties, wire clips, or adhesive tape to prevent them from getting tangled or interfering with moving parts. It is critical to ensure all connections are secure and well-insulated. Avoid short circuits. Check the wiring diagram for your specific RC components and follow the instructions carefully. Test the connections with a multimeter if needed. Proper wiring is essential for the RC car to function correctly and safely. Once the wiring is completed, make sure to double-check all connections before proceeding with the final assembly. This careful attention to detail ensures both performance and safety.

Installing the Receiver and Servo

Installing the receiver and servo are essential steps in completing the RC conversion. Begin by mounting the receiver securely within the chassis, away from potential sources of interference and damage. The receiver needs a clear line of sight to the transmitter. Position it in a way that does not obstruct the signal. Next, install the servo, which controls the steering mechanism. Mount the servo in a way that aligns with the steering linkage. Ensure the servo arm can move freely. Connect the servo to the steering linkage, using the appropriate servo horn and linkage connectors. Carefully route the servo wires, using zip ties or clips. Check the receiver channels, and confirm they match the transmitter settings. Make sure the servo and receiver connections are secure. Testing the steering and throttle functions is necessary after installing the receiver and servo. This helps identify and address any issues before final assembly. Accurate and secure installation of these components is vital for steering control and overall vehicle performance.

Chassis Modifications (If Needed)

Chassis modifications can be necessary to ensure all components fit and function properly. These modifications often involve cutting, drilling, or shaping parts of the chassis. Before making any modifications, carefully plan the layout of all RC components. Identify any areas where parts may interfere with each other or the model’s body. Use a Dremel or rotary tool with cutting, grinding, and sanding bits to remove material or create openings for the components. You might need to drill holes to mount the motor, servo, or other parts. Be precise with measurements and cuts to avoid damaging the chassis. If using a metal chassis, consider using appropriate tools like metal shears or files. Always prioritize the structural integrity of the chassis. After making the modifications, clean the area to remove any debris. Any necessary modifications ensure all components can be installed securely. The chassis should provide a solid and stable foundation for the RC components. Carefully executed chassis modifications are key for a smooth and reliable RC conversion.

Reassembly and Testing

Once all the RC components are installed and the chassis modifications are complete, the reassembly and testing phase begins. Reassemble the diecast model, carefully putting the body back together, ensuring all parts align correctly. Double-check all screws, clips, and fasteners to ensure they are securely in place. After reassembly, it’s time to test. Connect the battery and power on the RC system. Use the transmitter to control the car, testing the steering, throttle, and any other functions. Check the car’s response to your inputs. Make adjustments as needed. Ensure all components function correctly. Check the steering, acceleration, and braking. Run the car at different speeds and on different surfaces. The testing will reveal any problems and help you fine-tune the car’s performance. Also, observe the car’s behavior and handling. The testing phase identifies any issues and allows for adjustments. These could be to the steering or suspension. It’s important to make these adjustments before finalizing the build. This thorough testing ensures your converted model is ready for use and provides an enjoyable experience.

Testing and Calibration

Testing and calibration are crucial steps to ensure your RC converted diecast model operates correctly. Start by testing the steering, checking that the wheels turn smoothly and the steering response is proportional to your transmitter inputs. Next, test the throttle, ensuring the motor responds appropriately to your control inputs. The car should accelerate and decelerate smoothly. Check the car’s range. Walk away from the car while operating the controls. Verify that the car responds to your input. Calibrating the ESC is another critical step. Follow the manufacturer’s instructions. This process ensures that the ESC recognizes the full range of throttle input. Make sure the servo is properly centered. Often, the transmitter has a trim adjustment for this purpose. Fine-tune the car’s handling by adjusting the suspension, ride height, and other settings. Testing on various surfaces can help you identify and resolve any issues. Make sure that the car handles well. Testing and calibrating the RC components is essential. It ensures optimal performance and a safe and enjoyable experience.

Troubleshooting Common Issues

Troubleshooting is a critical aspect of RC conversion. Numerous issues can arise during the process, requiring methodical problem-solving. One common problem is that the motor doesn’t run. Start by checking the battery charge, the ESC connections, and motor wiring. Ensure the ESC is properly calibrated. If the steering doesn’t work, check the servo connections, the steering linkage, and the transmitter settings. Make sure that the servo is centered and that the linkage is not binding. If the car has poor range, check the receiver antenna and any potential sources of interference. Make sure the transmitter and receiver are paired correctly. Excessive noise from the motor or gears can indicate a problem with the gear mesh or motor alignment. Adjust the gear mesh and motor alignment. Overheating components are another common problem. Ensure adequate airflow, consider using a heat sink, or select a more powerful motor if necessary. Take your time and methodically work through the system, identifying and resolving problems. Consulting online forums, and seeking assistance from experienced hobbyists, can be invaluable in troubleshooting complex issues. Identifying and addressing issues ensures optimal performance, safety, and enjoyment.

Upgrades and Customization

Upgrades and customization are essential for taking your RC converted diecast model to the next level. One popular upgrade is the battery. Replacing the original battery with a higher-capacity or higher-voltage battery can increase run time and performance. Upgrade the motor. Upgrading the motor to a brushless motor can significantly boost speed and power. This is a performance upgrade. Another upgrade is the servo. Upgrading the servo will give you improved steering precision and responsiveness. Suspension upgrades, such as better shocks or springs, can enhance handling and provide a smoother ride. You can also customize the model’s appearance, add LED lights. Consider adding custom decals, or repainting the body. This will enhance its aesthetic appeal. Replacing tires can improve grip and handling. Customizing the appearance is an opportunity for personal expression. Upgrading and customizing your RC car is a continual process, providing ongoing opportunities to enhance its performance, appearance, and your overall enjoyment of the hobby. It’s a journey of refinement and personalization.

Battery and Motor Upgrades

Battery and motor upgrades significantly improve the performance of your RC converted diecast model. When it comes to batteries, consider upgrading to a higher-capacity battery for longer run times. Lithium Polymer (LiPo) batteries are popular due to their high power-to-weight ratio. Ensure the battery is compatible with your ESC. Regarding motor upgrades, a brushless motor is a popular choice for increased speed, efficiency, and power. Brushless motors provide better control and often require an ESC designed for brushless operation. Select a motor appropriate for your model’s scale and chassis. Also, consider the gear ratio. Changing the gearing can further enhance performance. The right upgrades can provide a noticeable increase in speed and power. Careful consideration is necessary when upgrading batteries and motors. They will greatly enhance your RC car’s performance. Proper selection, installation, and care are crucial to ensure the longevity and safety of the RC system.

Advanced Customization Techniques

Advanced customization techniques are used to further refine and personalize your RC converted diecast model. Fabricating custom chassis parts allows you to optimize the component layout. Custom chassis parts may include motor mounts or battery trays. Painting and detailing the model body using advanced techniques such as airbrushing, or weathering effects can create a unique aesthetic. Installing custom lighting systems, including LED headlights, taillights, and underglow, adds to the model’s realism. The customization of interior details is an advanced technique. Modifying the suspension, including custom shocks or suspension arms, can improve handling. Adding custom wheels and tires can enhance both the appearance and performance. Custom electronics, such as a telemetry system that provides real-time data on speed, temperature, and battery voltage, adds functionality. These advanced customization techniques require a blend of technical skill and creativity. They allow you to create a truly unique and personalized RC model. These techniques demonstrate a level of dedication, expertise, and passion. The advanced customization turns your RC model into a work of art.

Where to Find Help and Resources

Numerous resources can help you with your diecast to RC conversion project. Online forums and communities are excellent places to ask questions and gain advice. Many forums, such as those dedicated to RC cars, are populated with experienced hobbyists eager to share their knowledge. YouTube is filled with tutorials. Many videos guide you through the process of RC conversion. The videos often include step-by-step instructions. Websites dedicated to RC cars provide guides, product reviews, and tips for successful builds. Local hobby shops can offer hands-on advice, product recommendations, and access to spare parts. Model car clubs and RC car racing groups are another way to connect with like-minded enthusiasts. They provide opportunities for learning and inspiration. Manufacturer websites are great sources of manuals and specifications. Look for detailed instructions on various RC components. Accessing these resources improves your skills and knowledge, helping you overcome challenges and enjoy the project. The information and support available will make your RC conversion project both successful and enjoyable. Leverage these resources to enhance your skills and make the most of your hobby.